As temperatures rise, ice cream enters its peak sales season. For enterprises, ice cream represents both profit points and the loss of the “disaster area.” According to studies, incorrect storage accounts for more than 30% of all ice cream losses. Although ice cream is still within its shelf life, ice crystals form on the surface and adhere to the packing, resulting in the premature loss of commercial value for products that have not expired. Many ice cream companies are lowering the temperature to lengthen the shelf life of their products, but they are also facing rising electricity costs. The cause of these issues is sometimes hidden in an unexpected detail: the refrigerator lighting system.

Storage temperature of ice cream

The most crucial ice cream preservation principle is maintaining a consistent temperature, usually below -18℃

If the temperature rises by 3℃, the shelf life of ice cream may be reduced by 50%. When freezer doors are frequently opened, external warm air rapidly enters, causing temperature fluctuations within the cabinet. This causes the ice cream surface to repeat freeze-thaw cycles, promoting ice crystal formation that compromises texture and creates bacterial growth risks. This explains why simply lowering temperatures fails to resolve surface ice crystal issues –The root cause lies in maintaining stable cold chain integrity rather than brute-force cooling.

Why the temperature of refrigerated display light affects Ice Cream Quality

In the modern commercial environment, refrigerated display lighting has transcended its basic illumination function to become a silent sales expert. For cold chain equipment manufacturers, professional ice cream lighting solutions can add significant value to their product offerings. While, for retailers, the professional LED light can not only extend the shelf life of frozen treats but also reduce energy costs. Más importante, lighting may make products more vibrant and appealing, boost customer dwell time, and drive sales growth; for consumers, professional lighting can provide a comfortable shopping atmosphere and elevate the overall purchasing experience.

How to Select Refrigerated Display Case Lighting That Meets Food Safety Standards

1. Avoid being deceived by appearances. The lighting selection is too bright and chilly, making the ice cream look poor and making it easier for customers to get visual fatigue. It is advised to use lights with a CRI > 90 and warm white light with a color temperature between 3000K and 4000K to enhance the appearance of ice cream.

2. Conserving energy. Low-voltage lamps and lanterns are unquestionably the best option because they use less electricity, are safe, and replace traditional T8 tubes with 24V low voltage.

3. When selecting lighting fixtures, cost should not be the sole determining factor. Avoid the “low-price priority” mindset, as many unbranded lighting products lack quality assurance. These fixtures are prone to damage, consume high levels of energy, and have hidden costs from frequent replacements that are difficult to estimate.

Ice Cream Lighting solutions

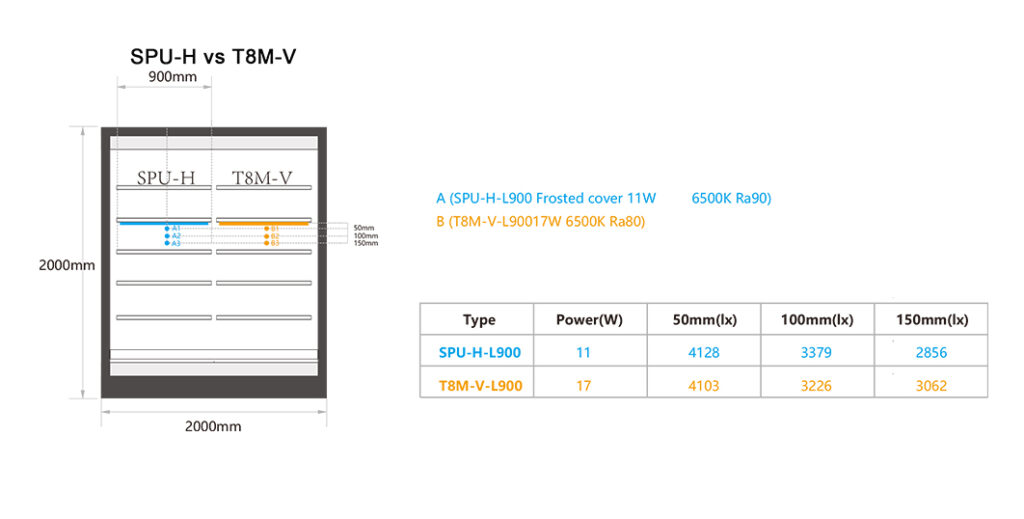

For the ice cream lighting system, the laidishine SPU series provides a revolutionary solution

1. The SPU series incorporates cutting-edge lens technology, enabling precise focusing of light onto product surfaces without generating stray light. With a Ra90+ high color rendering index, these refrigerated display case lights effectively showcase the appealing textures of merchandise.

2.24V low-voltage design, built-in aluminum, good heat dissipation, compared to the typical T8 tube, 35% ahorro de energía

3. The original equilateral triangle design allows for two mounting surfaces, and you may alter the angle of the light to enhance efficiency.

4. We have designed two types of brackets that support both magnetic and screw mounting options. For future light replacements, simply open the bracket to replace the fixture without needing to remove the entire unit, saving significant time and effort.

5. Laidishine upgraded the wire/harness systems for multi-deck showcases. Save 40% of time and effort.

Preguntas frecuentes

Q: What lumen output is required for refrigerated display case lighting?

A: It is recommended to configure 800-1200 lumens per meter of rail, with light distribution curves adjusted according to cabinet depth.

Q: How often should the lighting fixtures be replaced?

A: High-quality LED refrigerated display case lights have a lifespan of ≥50,000 hours. It is advisable to conduct light efficiency testing every 3 años.

Q: How to evaluate the return on investment (ROI) for lighting retrofits?

A: Case studies show:

Electricity cost savings: ¥1.2/day/cabinet

Loss reduction: ¥5.6/day/cabinet

Payback period: <8 months